A body of the European Union

A body of the European Union

A body of the European Union

A body of the European Union

Main benefits of the next generation of traction systems

- Energy savings of up to 10% for trains in all platforms: metro, light rail, sub-urban, regional and high-speed

- Quieter traction systems for all kinds of trains – up to 20 dB less noise for some parts

- Smart maintenance systems embedded in traction systems to lengthen train’s life, improve reliability and reduce maintenance costs up to 20%

Shift2Rail-funded engineers are developing the next generation of train traction systems – the vehicle’s propelling heart. New devices are expected to reduce up to 10% of full trains’ energy consumption when they reach the market in 2024. Read more below on Shift2Rail results as of the end of 2018, and watch out for new developments on their way!

The Challenge: Traction systems are one of the main components of a train: they convert electricity from the grid into usable energy able to move the vehicle. New prototypes under development by Shift2Rail partners seek reducing traction system’s power consumption, which could have a great impact as these parts account for up to 70% of the total vehicle consumption. New models should also be quieter, ensure more efficient cooling and include smart maintenance features allowing for lower life-cycle costs.

The Solution: To reduce traction system’s energy consumption, partners are developing new traction components using Silicon Carbide (SiC), a material with capability forgreat switching frequency, leading to higher efficiency rates. These exceptional properties make SiC MOSFET (Metal Oxide Semiconductor Field Effect Transistor) ideal in designing new more efficient converters than the ones based on Si-IGBT (Insulated Gate Bipolar Transistor) currently in use.

In 2018, Shift2Rail members developed prototypes for new traction converters achieving energy savings for the overall vehicle of 7% in metro, 4% in tramways, 5% in sub-urban and 9% in regional trains. Future prototypes under development are expected to slash train energy bills by up to 10% and reduce traction maintenance cost up to 20%.

Complementary to these innovative solutions for Tractions devices, Shift2Rail members are also devising a motor designed to be placed directly on the wheels. This Motorized Independent Wheel architecture will enable the implementation of additional engines to provide 2.4 MW of extra power to wheels, enabling European high-speed trains to reach 360 km/h (30 km/h faster than today). Faster trains would allow more vehicles to run on the same track, increasing the line’s passenger capacity.

Next generation of traction systems will be quieter too. One of the best examples is the reduction of noise emissions from main transformers in sub-urban trains, with prototypes in development producing 20dB less electromagnetic noise than those in service on sub-urban trains. Additionally, highly accurate computational models will allow manufacturers to better predict the cooling noise performance of new traction systems before actually building them, hence saving time and money.

New prototypes will include smart maintenance systems, able to perform remote diagnosis and health monitoring, reducing maintenance costs and improving reliability of traction systems. Trains would have a higher punctuality rate; which is especially crucial for transport in ‘megacities’.

Moving towards market uptake: Work on the next generation of traction systems has been undertaken by the Shift2Rail project PINTA that finished in December 2018. Shift2Rail partners are taking the developments forward in project PINTA-2. Through this collaborative work, Shift2Rail partners plan to bring a more efficient traction system to the market by 2024.

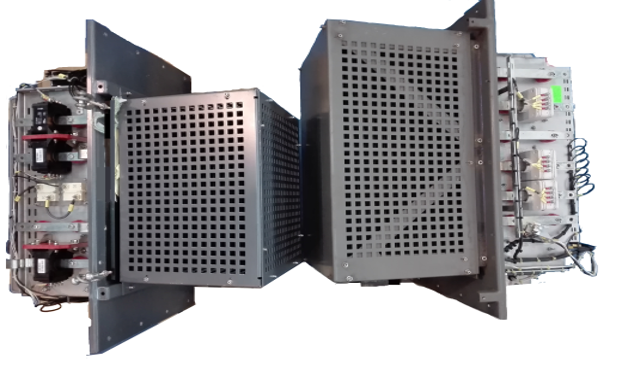

An example of volume reduction thanks to the use of SiC